our aerospace line is growing

For quotes or more information please contact us at (866) 433-4768 or sales@rockymountaintwist.com

Expanded Aerospace Line:

- Countersinks in HSS, M42, solid carbide & carbide tipped HSS removable pilot, carbide tipped removable pilot and M42 removable pilot

- Aircraft counterbores in HSS, M42, and carbide tipped

- Carbide tip rivet shavers

- Countersink pilots

- Reverse spotfacers and reverse countersinks in HSS, M42, carbide tipped and solid carbide

- Hollow cutters in HSS and M42

- 6" Arbor pilot for reverse spotfacer, countersinks

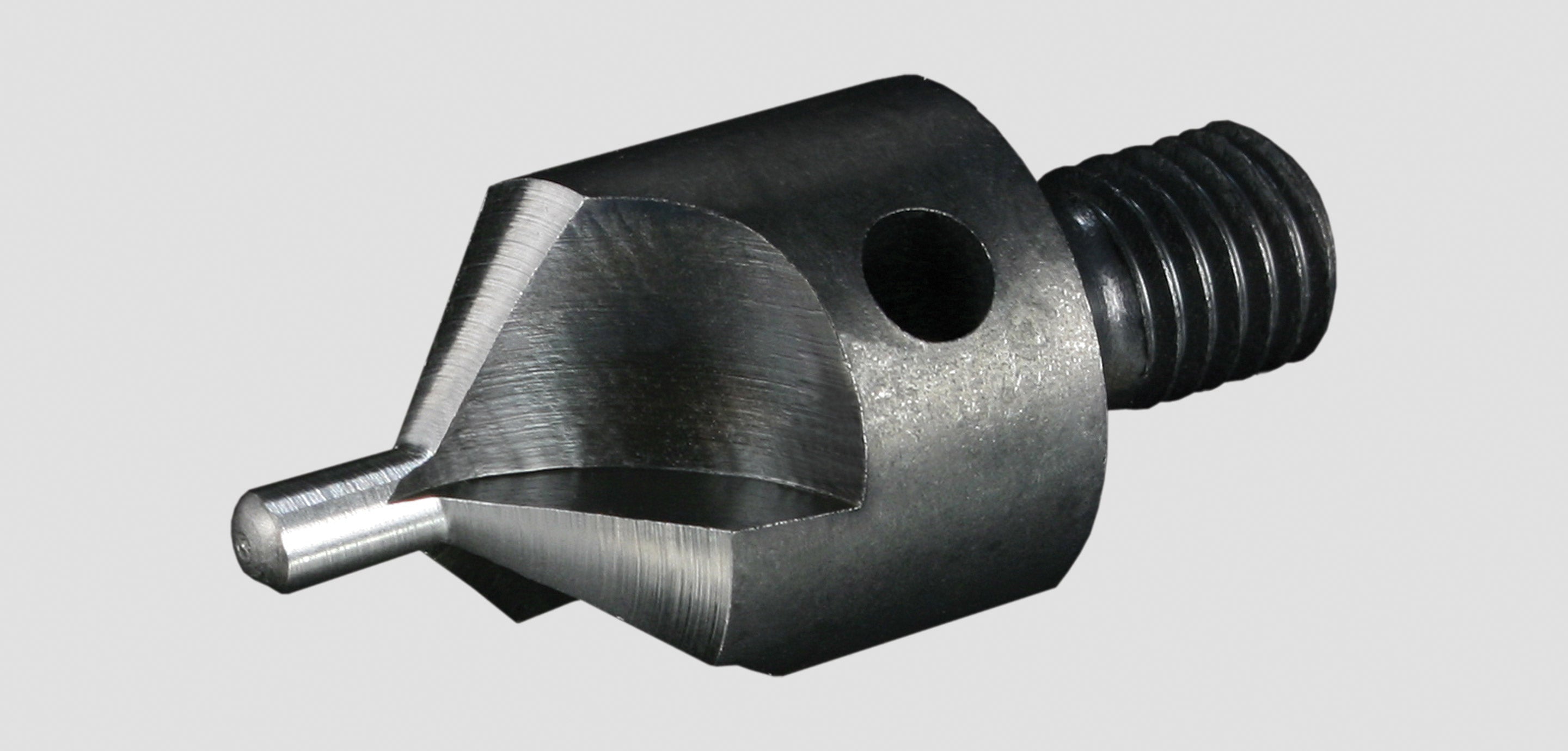

TRI-CAM microstop countersink

- Tri-cam design for true concentric fastener interface

- Precision, CNC diamond machined ensures exact specifications and consistency

- Premium M2 High Speed Tool Steel

- Premium M42 Cobalt HSS

- A countersink is used to cut and form a hole so that a flush fastener can be installed

- The main features of this countersink is the threaded shank, body cutting angle, and pilot

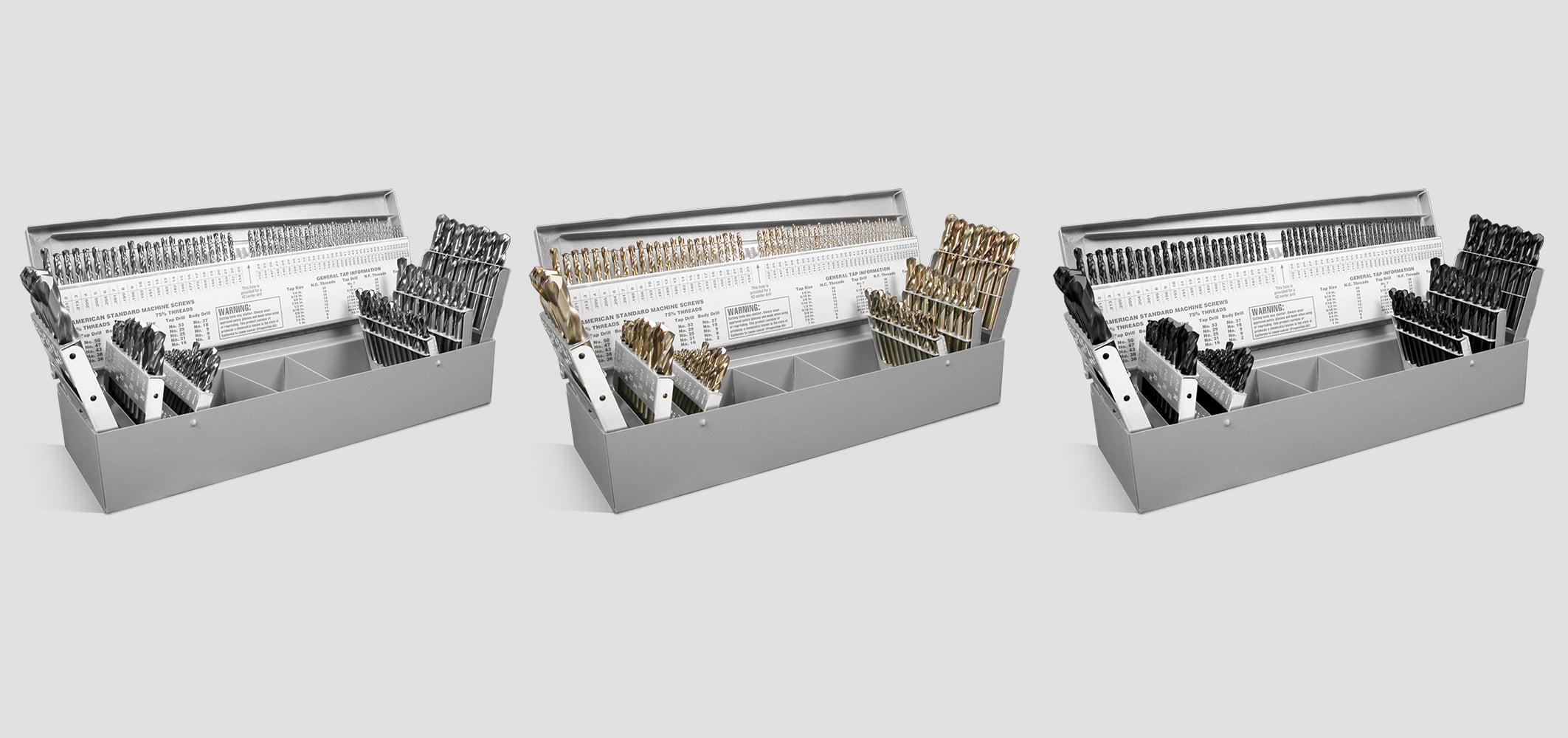

6" & 12" Aircraft extension

- One piece construction for long lasting durability and strength

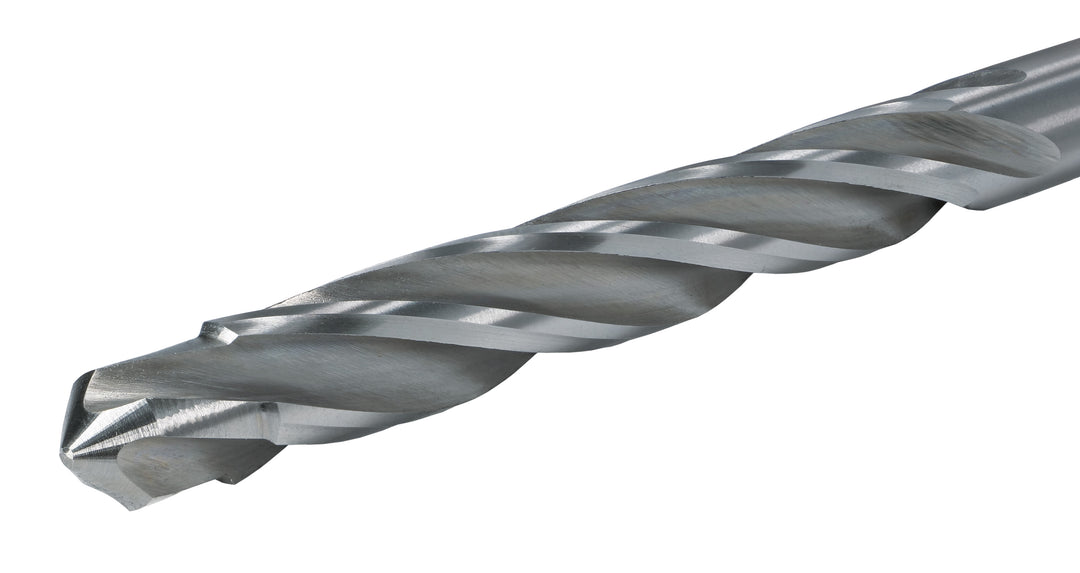

- 135° Split point is self centering to help reduce the thrust requirements

- Split point penetrates on contact and prevents "walking" of the bit

- Industrial-Grade NAS construction (HSS and Cobalt)

- Heavy duty jobber flute length drills that are used for drilling holes in hard to reach places

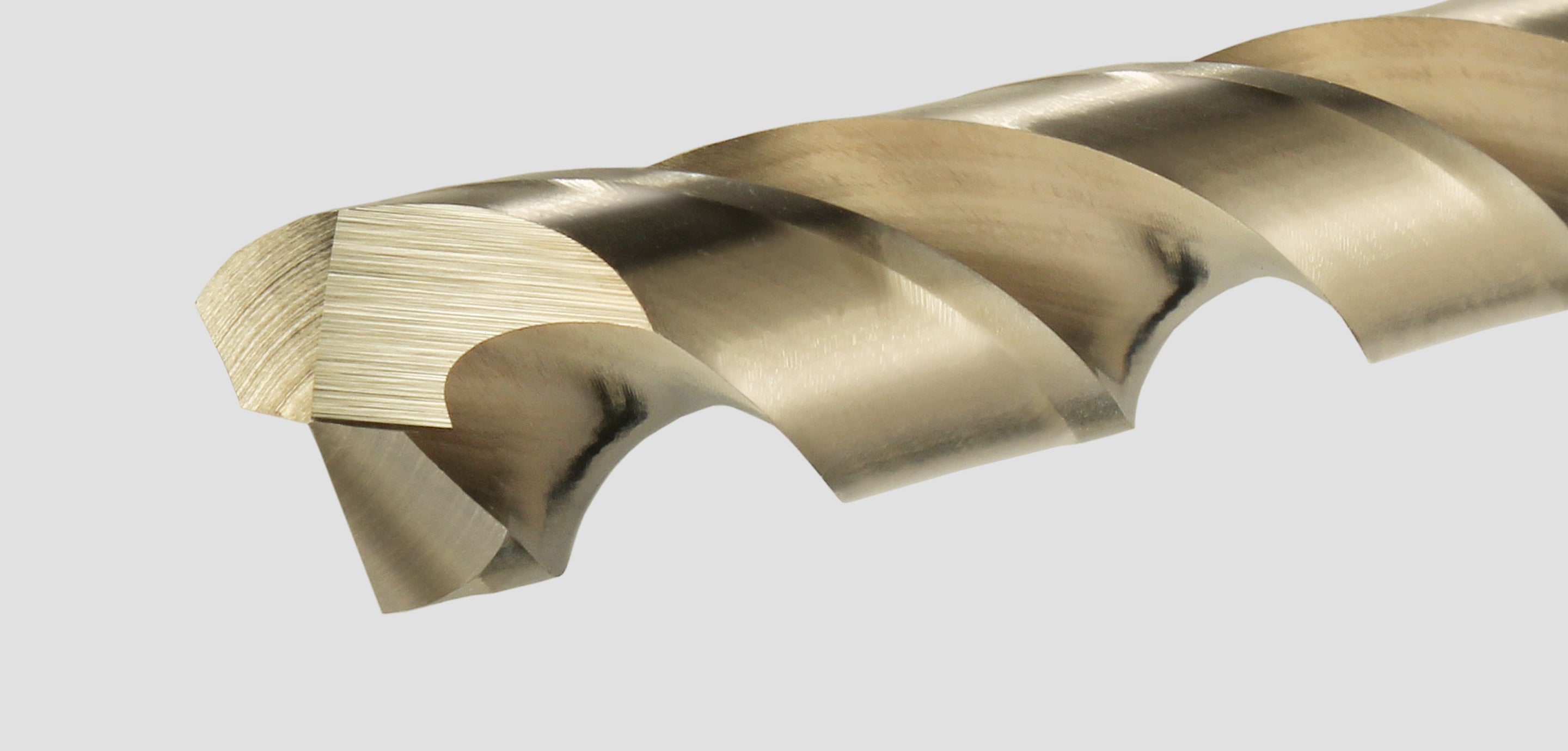

Double Margin Core

- Four equally spaced CNC ground flutes for rounder holes

- Heavy Duty core construction

- Industrial-Grade NAS construction (HSS and Cobalt)

- Pilot/Major O.D. combinations to suit customer needs

- Double margin drills have an additional margin ground behind the leading margin, providing twice the number of contact points

- The trailing margin burnishes the cavity, making a true hole and smoother finish, helping to provide a more concentric drilled hole

- A reamer finish can be achieved with double margin drills, eliminating a second operation

Threaded shank

- Constructed from Industrial-Grade NAS Steel

- Able to screw into a threaded adapter on a handheld drill to enable drilling in tight areas where standard bits that install in a chuck can't fit

- Commonly used for angle and offset drilling

- Split point penetrates on contact and prevents "walking" of the bit

- Very stub configurations available

- Built to NAS 965

Nutplate drills

- One piece construction

- Oversized cross-hole for easy removal

- Tempered shank prevents breakage

- Premium M42 Cobalt HSS

- These machine specific drills are used with nutplate jigs in order to produce a high volume of holes that are to size with consistent hole spacing